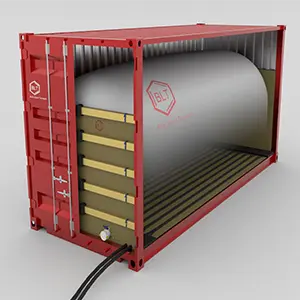

Flexitank, also known as flexitank container, Container flexi bag, etc. Flexitank can make full use of the capacity of the container to the greatest extent and reduce packaging and handling costs.

The fitting of flexitanks and the loading and unloading of goods are relatively simple, which improves transportation efficiency.

Single-use flexitanks require no cleaning or maintenance, which reduces the effort and cost of subsequent disposal.

Flexitanks are highly sealable, and each of your flexitanks is brand new and will not cause cross-contamination of the product.

Flexitanks can be loaded by different modes of transportation( shipping, rail, road, etc.), and intermodality does not require changing the packaging.

After use, flexitanks can be recycled into plastic raw material production to reduce environmental impact and increase sustainability.

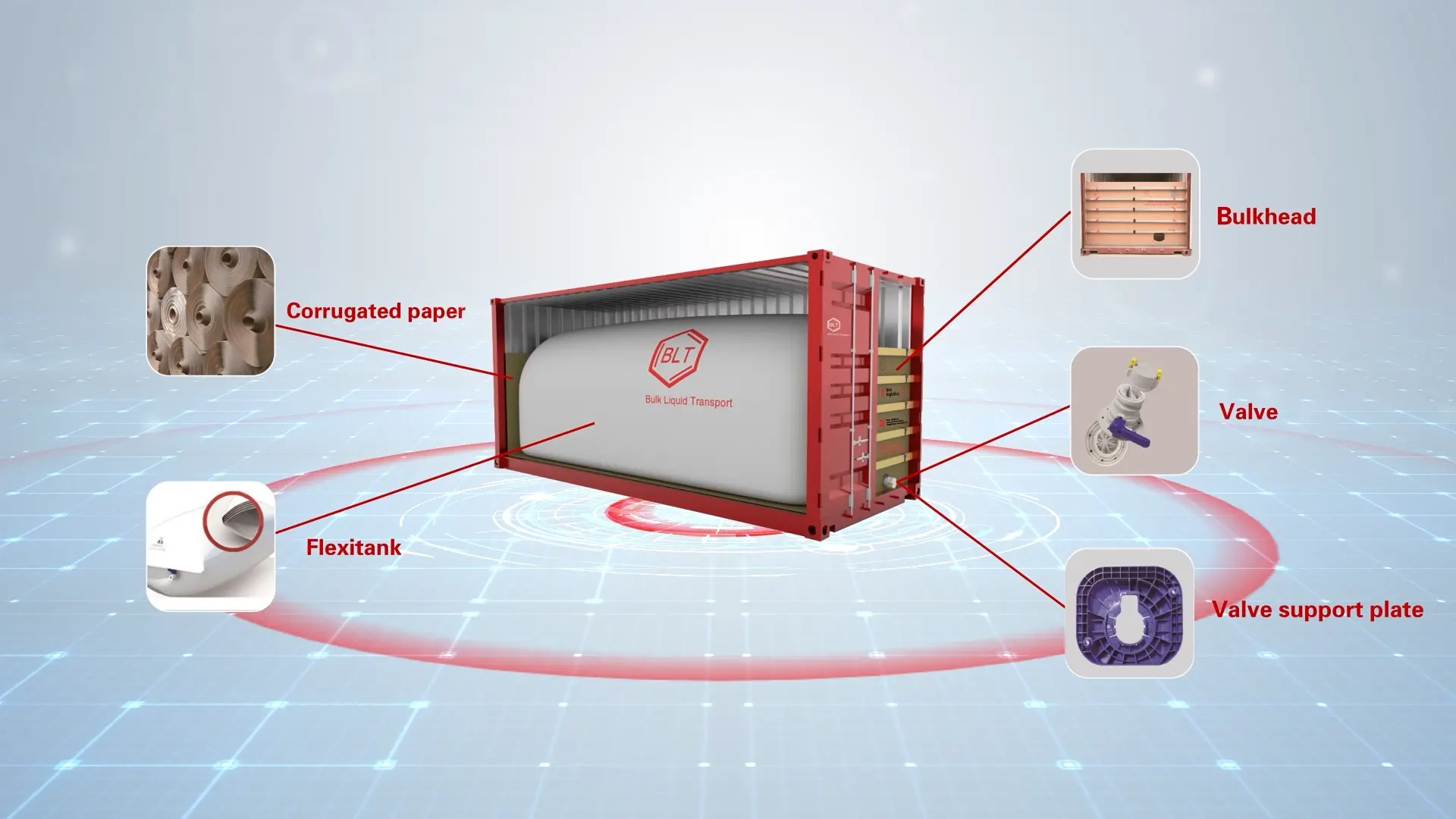

Flexitank systems are designed to handle a wide range of non-hazardous liquids, including food-grade products, industrial chemicals, and oils. In addition to the flexitank itself, these systems often include various accessories and components such as valves, hoses, and heating pads, which ensure ease of loading and unloading, as well as temperature control during transit.

Key benefits of flexitank systems include significant cost savings compared to traditional packaging methods like drums or IBCs, reduced environmental impact due to lower packaging waste, and the ability to transport large volumes in a single trip. These systems are ideal for companies seeking a reliable, scalable, and environmentally friendly solution for bulk liquid logistics.